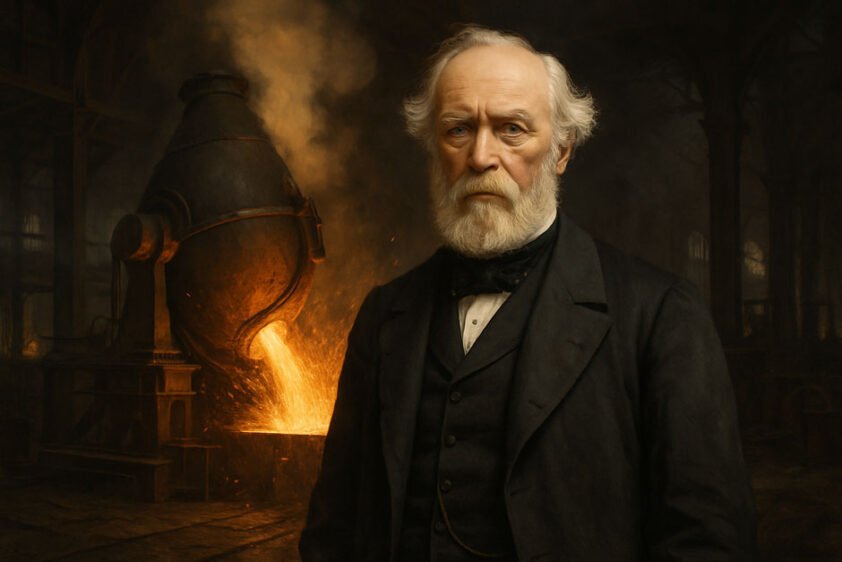

What single invention could be credited with building the modern world, from the towering skyscrapers of New York to the vast railway networks spanning continents? The answer lies with Henry Bessemer, an English engineer whose revolutionary process for mass-producing steel transformed industry and society forever.

Born in 1813 in Charlton, Hertfordshire, Henry Bessemer was the son of an engineer and typefounder, Anthony Bessemer. From an early age, the younger Bessemer displayed a remarkable aptitude for mechanical skill and invention, a trait that would define his long and prosperous life.

Unlike many inventors who struggled financially, Bessemer was a shrewd businessman who found success early on. His initial inventions included improvements to a typesetting machine and, most lucratively, a secret process for manufacturing “gold” powder from brass for use in paints. This early financial independence allowed him to pursue his true passion: metallurgy.

The Man Behind the Steel Revolution: Sir Henry Bessemer

Early Life and a Flair for Invention

Bessemer’s early success was a testament to his inventive spirit, securing him the capital needed for his later, more ambitious projects. He was not a man to be constrained by a single field, holding over a hundred patents across various industries.

His early work on movable stamps for government documents and sugarcane-crushing machinery demonstrated a mind constantly seeking efficiency and improvement. Yet, it is his name’s association with steel that has cemented his place in history.

A Military Problem and a New Idea

The spark for his greatest invention came not from a desire to build cities, but from the grim necessity of war. During the Crimean War in the mid-1850s, Bessemer was working on a new type of elongated artillery shell for the French authorities.

The French, however, pointed out that their cast-iron cannons were not strong enough to withstand the forces generated by his powerful new shells. This challenge shifted Bessemer’s focus from the projectile to the material itself.

He set out to produce a stronger, more reliable cast iron. In his experiments, he made a crucial observation: the excess oxygen in his furnace seemed to be removing the carbon from the molten iron.

The Accidental Discovery: Birth of the Bessemer Process

The Simple Yet Revolutionary Mechanism

At the time, steel was a luxury material, costly and slow to produce, primarily used for small items like tools and cutlery. The existing method for refining iron, known as puddling, was laborious and manual.

Bessemer’s genius lay in its simplicity. He realized that by blowing jets of air through molten pig iron, the oxygen would react with the impurities—primarily carbon and silicon—burning them off.

This reaction was not only a purification process but also an autogenous one, meaning the chemical reaction itself generated intense heat. This allowed the purified iron to remain molten and be easily poured, a feat impossible with previous methods.

The Result: Steel for the Masses

The result was a material that was strong, uniform, and, most importantly, cheap. The Bessemer Process made steel easier, quicker, and dramatically less expensive to manufacture than ever before.

This invention effectively turned steel from a scarce commodity into a mass-produced construction material. It was a technological leap that immediately captured the attention of industrialists worldwide.

Forging the Modern World: Bessemer’s Enduring Impact

The Second Industrial Revolution

The impact of cheap steel was immediate and profound, acting as a catalyst for the Second Industrial Revolution. Suddenly, engineers had access to a material strong enough to support unprecedented structures.

The new steel was used to build stronger, safer, and faster railroads, replacing older, weaker iron tracks. It enabled the construction of massive steamships and the revolutionary suspension bridges and skyscrapers that defined the modern urban landscape.

Cities like Sheffield, England, nicknamed the “Steel City,” grew into major industrial centers, their fortunes tied directly to the success of Bessemer’s innovation. His process fundamentally reshaped global industry and trade.

Beyond the Converter: Other Inventions

While the Bessemer Process remains his most famous contribution, Sir Henry Bessemer was a prolific inventor who registered over 129 patents throughout his life. His inventive curiosity extended far beyond metallurgy.

One notable, though commercially unsuccessful, invention was the SS Bessemer, a passenger steamship designed to combat seasickness. It featured a cabin mounted on gimbals, intended to keep the passengers level regardless of the rough seas.

He also patented a method for the continuous casting of metal between contrarotating rollers, a concept that was a remarkable forerunner of modern continuous casting processes used in steel production today.

A Lasting Legacy

Honors and Recognition

Bessemer’s contributions did not go unrecognized in his lifetime. He was knighted by Queen Victoria in 1879 for his services to science and was made a Fellow of the Royal Society in the same year.

His legacy is honored annually through the prestigious Bessemer Gold Medal, awarded for outstanding services to the steel industry. Furthermore, his name lives on in the geography of the industrial world.

Cities and towns in the United States, and streets and pubs in his native England, bear his name, a constant reminder of the man who gave the world the backbone of its infrastructure. Henry Bessemer did not just invent a process; he engineered the foundation of the world we inhabit today.